- Home

- About us

- Our Products

- SAILMA 550HI Steel Plates

- SAILMA 450HI Steel Plates

- SAILMA 350HI Steel Plates

- Corten B Steel Plates

- CORTEN A Steel Plates

- Corten Steel Wall Cladding

- IS 2062 E410C Plates

- S355JR Plates

- Stainless Steel Facade

- S355J2+N Steel Plates

- S355J2G3 Grade Steel Plates

- S355J2N / IS 2062 E350C

- Corten Steel Facade

- IRSM 41-97 Steel Plates / Corten A

- ASME SA 516 Grade 70 BQ Plates

- ASME SA 516 GRADE 60 BQ PLATES

- ASME SA 516 GR.60/70N DUAL CERTIFIED PLATES

- S355J2W+N Steel Plates for Railways

- ASME SA 516 GRADE 70N NACE AND HIC PLATES

- IS 2062 E410 GRADE BR PLATES (E410BR/B0/C)

- ASME SA 516 GRADE 60/70N NACE AND HIC PLATES

- IS 2062 E350 Sailma Grade Plates (E350/E350BR/E350C)

- IS 2062 E450 SAILMA Plates (E450BR / E450B0 / E450C)

- IS 2062 E450 SAILMA Plates (E450BR / E450B0 / E450C)

- Blogs

- Contact

- Home

- About us

- Our Products

- SAILMA 550HI Steel Plates

- SAILMA 450HI Steel Plates

- SAILMA 350HI Steel Plates

- Corten B Steel Plates

- CORTEN A Steel Plates

- Corten Steel Wall Cladding

- IS 2062 E410C Plates

- S355JR Plates

- Stainless Steel Facade

- S355J2+N Steel Plates

- S355J2G3 Grade Steel Plates

- S355J2N / IS 2062 E350C

- Corten Steel Facade

- IRSM 41-97 Steel Plates / Corten A

- ASME SA 516 Grade 70 BQ Plates

- ASME SA 516 GRADE 60 BQ PLATES

- ASME SA 516 GR.60/70N DUAL CERTIFIED PLATES

- S355J2W+N Steel Plates for Railways

- ASME SA 516 GRADE 70N NACE AND HIC PLATES

- IS 2062 E410 GRADE BR PLATES (E410BR/B0/C)

- ASME SA 516 GRADE 60/70N NACE AND HIC PLATES

- IS 2062 E350 Sailma Grade Plates (E350/E350BR/E350C)

- IS 2062 E450 SAILMA Plates (E450BR / E450B0 / E450C)

- IS 2062 E450 SAILMA Plates (E450BR / E450B0 / E450C)

- Blogs

- Contact

Boiler Steel Plate SA 516 Grade 70 Nace HIC Plate Supplier in India

SAILMA 550HI Steel Plates

April 9, 2024

Corten steel cladding suppliers near me

April 9, 2024What is Boiler Steel Plate

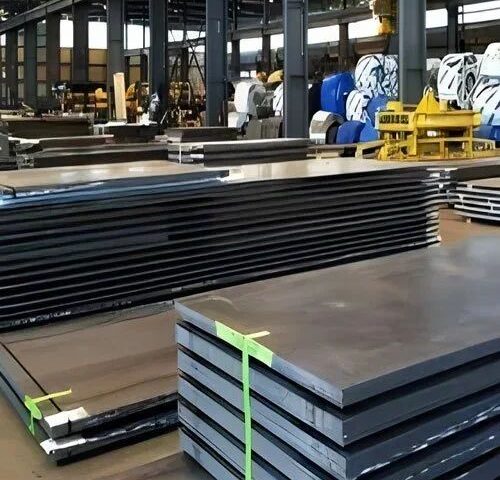

Boiler steel plate are one of the special kinds of Steel Plates for use under one’s boilers and attached pressure vessels. In essence, the forming of such steel is done rigorously, with a specialized formulation and characteristics to make it suitable for environments with high strength and conditions toward extremely temperate and pressurized regions.

Boiler steel plates are a critical material used in many industries and most often in the power generation and manufacturing sectors, where most components that are exposed deal with high-temperature and high-pressure conditions. The discussion on boiler steel plates includes their composition, properties, applications, advantages, and a consideration in the selection of the right material.

Composition and Properties of Boiler Steel Plate

Alloying Elements: The steel, mostly found in the boiler steel plate, contains other alloys such as carbon, manganese, and silicon, and added amounts of alloying elements like molybdenum and nickel in variation from nominal 3% up to 12% to produce high strength and corrosion resistance for the steel produced for applications where demand or usage is substantially high.

Mechanical Properties: Boiler Steel Plates have excellent mechanical properties such as high tensile, high yield, and tensile strength, resistant to brittleness at lower temperatures. This property of material provides structural strength and durability in increased operating temperatures and other conditions.

Applications of Boiler Steel Plate

Boiler Manufacturing: Boiler steel plates address the fabrication of boilers in power generation, petrochemicals, and food processing. The plates form the structural framework within a boiler, which gives support and confinement of high-pressure steam generation.

Power Generation Plants: Boiler steel plates are key equipment in boilers and turbines, to other adjunct in-service equipment in power generation plants. They are capable of even high temperatures and pressure made while producing. This helps the plates convert power effectively and, therefore, continuously produce power. Pressure Vessels Boiler steel plates are also used in the making of pressure vessels for storage and transporting gases and liquids, which are under high pressure. These are very important vessels used in industries, among other things, oil and gas, chemical processing, and aerospace.

Equivalent Grade of Boiler Steel Plate

Boiler Steel SA 516 Grade 70 NACE Plate, SA 516 Grade 70 NACE Plate, Boiler Steel Plate, SA 516 Grade 70 Plate, NACE Plate, Boiler Grade Steel, SA 516 Steel Plate, Grade 70 NACE Plate, Boiler Plate Grade 70, NACE Certified Plate, SA 516 NACE Plate, Steel Plate Grade 70, NACE Boiler Plate, SA 516 Grade 70 Steel, NACE Certified Steel Plate, Boiler Steel Plate Grade 70, SA 516 Grade 70 NACE Certified Plate, Grade 70 Boiler Plate, SA 516 NACE Certified Plate, Boiler Grade Steel Plate, SA 516 Grade 70 NACE Steel Plate, NACE Approved Plate, SA 516 Grade 70 NACE Certified Steel Plate, Grade 70 NACE Certified Plate, NACE Approved Steel Plate ASTM A516 GRADE 70 BOILER QUALITY PLATES, SA516 GRADE 70 PRESSURE VESSEL PLATES, SA 516 GR.60/70N DUAL, SA 516 GR.60 Plates, SA 516 GR.70 Plates, SA 516 GR.60/70N DUAL SA 537 CL.1 Plates, SA 516 GR.70 Plates, SA 537 CL.2 Plates SA 515 GR.60 Plates, SA 515 GR.70 Plates, SA 285 GR.A Plates, SA 285 GR.B Plates, SA 285 GR.C Plates ASME SA516 GRADE 70 PRESSURE VESSEL & BOILER PLATES, ASTM A516 GR 70 BOILER & PRESSURE VESSEL STOCKIST IN MUMBAI, INDIA. ASTM A516 GR 70 BOILER PLATES EXPORTER, ASME SA516 GR 70 CARBON STEEL PLATE SUPPLIER IN INDIA.

Advantages of Boiler Steel Plate

High-Temperature Resistance: The boiler steel plates of such resistance bear a property that they can support, for example, the high temperature reached by boilers and pressure containers, without deforming or getting impaired with extremely superior resistance.

Corrosion Resistance: The boiler steel plates, on the other hand, are designed to resist corrosion so as not to produce rust, etc., to cause deterioration in a corrosive environment. This works well for the maintainability, long-term durability, and reliability of the boilers and pressure vessels.

Strength and Toughness: Boiler steel plates provide very high strength and toughness that can allow mechanical stresses and impacts without failing. This property is of immense importance in the preservation of structural integrity and safety in demanding applications.

Boiler steel plates are available in various types based on their composition and properties:

Carbon Steel: Economical and versatile, suitable for general-purpose applications.

Alloy Steel: Enhanced with alloying elements for improved strength and corrosion resistance.

Stainless Steel: Provides superior corrosion resistance and hygiene for specialized applications.

FAQs

Q1. Can boiler steel plates withstand sudden changes in temperature and pressure?

Yes, boiler steel plates are engineered to withstand extreme operating conditions, including rapid temperature and pressure fluctuations, without compromising structural integrity.

Q2. Are boiler steel plates susceptible to corrosion in high-temperature environments?

While boiler steel plates offer corrosion resistance, prolonged exposure to aggressive chemicals and high temperatures may necessitate additional protective measures such as coatings or insulation.

Q3. What is the typical lifespan of boiler steel plates in industrial applications?

The lifespan of boiler steel plates varies depending on factors such as operating conditions, maintenance practices, and material quality. With proper care and maintenance, they can last several decades.

Q4. Can boiler steel plates be repaired if damaged during operation?

Yes, minor damages to boiler steel plates can be repaired through welding or patching techniques. However, extensive damage may require replacement to ensure structural integrity and safety.

Q5. How do boiler steel plates contribute to energy efficiency in power generation plants?

Boiler steel plates enable the efficient generation and transfer of heat energy, minimizing energy losses and optimizing the performance of boilers and steam turbines in power generation plants.