Features of Stainless Steel Facade

Stainless steel facades are a popular choice for both commercial and residential buildings due to their durability, aesthetics, and low maintenance requirements.

>>What is Stainless Steel Facade

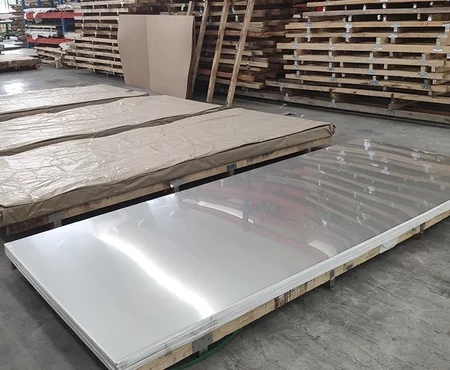

A stainless steel facade refers to the use of stainless steel as the primary material for the exterior cladding or covering of a building’s facade. In architectural and construction contexts, a facade is the front-facing exterior wall or the face of a building that is visible to the public. Stainless steel is used as a cladding material to provide a sleek, modern, and durable appearance to a building’s exterior.

Corrosion Resistance: Stainless steel is highly resistant to corrosion and rust, making it ideal for exterior applications. It can withstand exposure to harsh weather conditions and environmental factors without deteriorating.

Durability: Stainless steel is known for its long-lasting durability. It can withstand physical impact, temperature fluctuations, and other stresses without showing significant wear and tear.

Aesthetic Appeal: Stainless steel has a modern and sleek appearance that can enhance the visual appeal of a building. It can be polished to a high shine or given various finishes to achieve different looks, including brushed, satin, or textured finishes.

Low Maintenance: Stainless steel requires minimal maintenance. It is easy to clean and does not require painting or sealing, reducing long-term maintenance costs.

Stainless Steel Facade, STAINLESS STEEL 409M INDUSTRIAL PLATES, STAINLESS STEEL 409M PLATES, 409M STEEL PLATES, ASTM A240 409M STAINLESS STEEL PLATES, STAINLESS STEEL 409M PLATE DISTRIBUTOR, STAINLESS STEEL GRADE 409M PLATES STOCKIST IN MUMBAI, INDIA.,

SS 409M HR PLATES DEALER, SS 409M PLATES EXPORTER, 409M STAINLESS STEEL HOT ROLLED PLATE, 409M STAINLESS STEEL CHEQUERED PLATE, STAINLESS STEEL 409M 2B FINISH PLATE, GRADE 409M STAINLESS STEEL PLATES SUPPLIER IN INDIA.

>> Equivalent Grade of Stainless steel Facade

The concept of an “equivalent grade” for a stainless steel facade is a bit different from how materials are typically categorized in the stainless steel industry. Stainless steel materials are usually classified by their chemical composition and grade, and these grades are standardized based on specific properties and characteristics, such as corrosion resistance, strength, and heat resistance.

Common stainless steel grades used for facades and architectural applications include:

304 Stainless Steel: This is one of the most widely used stainless steel grades for facades. It offers good corrosion resistance and is often chosen for its aesthetic qualities.

316 Stainless Steel: This grade is known for its superior corrosion resistance, making it suitable for coastal or aggressive environments.

430 Stainless Steel: It is commonly used for architectural purposes and offers good corrosion resistance in less aggressive environments.

316L Stainless Steel: A low-carbon version of 316, offering improved weldability and corrosion resistance.

441 Stainless Steel: It is used for architectural applications and is known for its resistance to high-temperature oxidation.

The choice of an “equivalent grade” would depend on the specific requirements of the project and the properties desired. It’s important to consult with a materials expert or structural engineer to determine the most suitable stainless steel grade for your facade based on factors such as location, exposure, budget, and aesthetics.

>> Specifications of Stainless steel Facade

The specifications for a stainless steel facade can vary depending on the specific requirements of the building project and the design preferences. However, here are some common specifications that may be associated with a stainless steel facade:

Stainless Steel Grade: The choice of stainless steel grade is a crucial specification. Common grades for facades include 304, 316, 430, and others, depending on the desired level of corrosion resistance and aesthetics.

Finish: The finish of the stainless steel can vary, such as polished, brushed, satin, or textured. The finish can significantly impact the appearance of the facade.

Thickness: The thickness of the stainless steel panels or cladding will depend on factors like structural requirements and the design’s aesthetics. Common thicknesses range from 0.8mm to 3mm.

Panel Dimensions: Specify the dimensions (length, width, and thickness) of the stainless steel panels used in the facade.

Cladding Method: Determine how the stainless steel will be attached to the building’s structure. Common methods include adhesive, mechanical fastening, or curtain wall systems.

Support Structure: Detail the support structure for the stainless steel facade, which may include framing, subframes, or structural attachments.

Fixing Details: Specify the type of fasteners, anchors, or attachment methods used to secure the stainless steel panels to the support structure.

Design and Pattern: Provide design details, if any, regarding how the stainless steel panels are arranged, shaped, or patterned on the facade.

Corrosion Protection: Specify any additional corrosion protection measures, such as coatings or sealants, if needed.

Fire Safety: Ensure the facade complies with local fire safety regulations and specify any fire-resistant treatments or coatings.

SPECIFICATION

| Specifications | Stainless Steel Facade |

| Thickness | 4-5 mm |

| Steel Grade | SS304 L |

| Material | Stainless Steel |

| Color | Blue |

| Surface Treatment | Painted |

| Brand | Tenso |

>> Chemical Composition of Stainless steel Facade

A stainless steel facade is not a specific type of stainless steel material but rather a design or architectural application of stainless steel. Stainless steel itself is a family of corrosion-resistant steel alloys with a minimum of 10.5% chromium content. The specific chemical composition of stainless steel used in a facade will depend on the chosen grade of stainless steel. Different stainless steel grades have varying compositions to achieve specific properties and characteristics.

Here is the general chemical composition of stainless steel, based on the most common stainless steel grades, like 304 and 316:

Chromium (Cr): Typically, stainless steel contains at least 10.5% chromium. Chromium is essential for providing corrosion resistance by forming a passive oxide layer on the surface.

Nickel (Ni): Some stainless steel grades, like 304 and 316, contain nickel, which enhances corrosion resistance, durability, and ductility.

Carbon (C): Stainless steel has a low carbon content, usually less than 0.08%. Low carbon content is essential to maintain corrosion resistance and prevent sensitization during welding.

Manganese (Mn): Manganese is added to improve the formability and strength of stainless steel.

Silicon (Si): Silicon is present to aid in deoxidization and improve the resistance to scaling at high temperatures.

Phosphorus (P) and Sulfur (S): These elements are usually kept to low levels to maintain the material’s purity and corrosion resistance.

Molybdenum (Mo): Molybdenum is often added to certain stainless steel grades (e.g., 316) to enhance resistance to pitting and crevice corrosion, especially in chloride-rich environments.

Other Elements: Depending on the specific stainless steel grade, other elements like nitrogen (N), copper (Cu), and niobium (Nb) may be present in varying amounts to achieve particular properties.

>> Mechanical Properties of Stainless steel Facade

The mechanical properties of a stainless steel facade, or any stainless steel material used in construction, are essential to ensure that the facade meets the structural requirements of the building while maintaining its integrity and appearance. These properties can vary depending on the specific grade of stainless steel used, and the properties are typically determined through testing and analysis. Here are some of the key mechanical properties of stainless steel:

Tensile Strength: Tensile strength measures the maximum stress that a material can endure while being stretched or pulled. Stainless steel is known for its high tensile strength, which makes it suitable for load-bearing applications.

Yield Strength: Yield strength is the amount of stress at which a material begins to deform plastically. It is an important property for determining the material’s ability to withstand loads without permanent deformation.

Elongation: Elongation is a measure of how much a material can stretch or deform before it breaks. Stainless steel typically has good elongation properties, allowing it to deform to some extent without fracturing.

Modulus of Elasticity (Young’s Modulus): This property represents the material’s stiffness and its ability to return to its original shape after deformation. Stainless steel has a high modulus of elasticity, indicating that it is relatively rigid.

Hardness: Hardness measures the resistance of a material to indentation or scratching. Stainless steel can be hardened to varying degrees, depending on the grade and heat treatment.

Impact Resistance: Impact resistance measures the ability of the material to absorb energy when subjected to sudden forces, such as impacts. This property is important for assessing how well the stainless steel can withstand external forces.

Fracture Toughness: Fracture toughness indicates a material’s resistance to crack propagation. It is crucial for assessing the material’s ability to resist the initiation and growth of cracks.

Fatigue Strength: Fatigue strength is the ability of the material to withstand cyclic or repeated loading without failing. It is particularly important for materials exposed to dynamic loads, such as wind or vibrations.

Shear Strength: Shear strength measures the material’s resistance to forces applied parallel to its surface. It is important in applications where shear forces are a concern.

409M Steel Plate We Supply Worldwide :

Plate Size available Ex-Stock of SAILMA 550HI, SAILMA E550, IS 2062 E550

| 1mm | 2mm | 3mm | 4mm | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 20mm |

| 25mm | 30mm | 32mm | 36mm | 40mm | 45mm | 50mm | 63mm | 70mm | 72mm | 75mm |

| 80mm | 90mm | 100mm | 110mm | 130mm | 150mm | 170mm | 180mm | 200mm | 230mm | 270mm |

| 300mm |